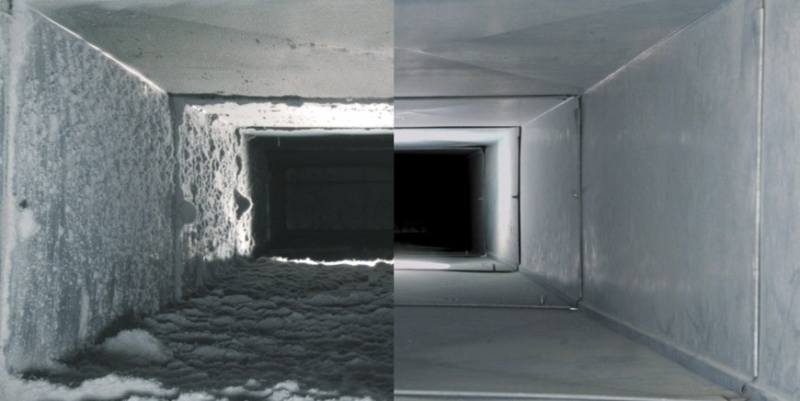

The main role of a professional kitchen hood is to collect the steam and oily cooking fumes and evacuate them to the outside. Throughout its journey, the grease is deposited on the filters, the hood, the duct, and on the extractor.

Accumulated grease is very aggressive on ferrous material (corrosion of sheaths, filters, and extractors which cause leaks, deterioration of neon lights, etc. ) and can even cause a fire.

It is for this reason that during the period of operation of a restaurant, the stale air extraction circuit of mist and grease must be maintained regularly and swept at least once a semester (twice a year).

Depending on the configuration of the technical installations, the type of catering offered in your establishment, and the number of meals provided daily, the degreasing of your extraction hood is required more or less frequently.

We can say that the number of annual interventions will be determined according to the type of food mainly cooked.

Why degrease the hood and the extraction network ?

The impeccable hygiene of a restaurant and any catering establishment determines its brand image and its reputation.

cleaning and degreasing grease extraction circuits is an essential operation for the health and safety of your customers and your kitchen staff.

Indeed, the degreasing of the kitchen hoods, the ducts for the extraction of greasy vapors as well as the extractor mainly makes it possible to avoid the biological contamination of food by organic residues and burnt fats.

In addition, deficient extraction results in smelly fumes, excessive heat, and odors, and in this case, you risk scaring away your customers!

Thanks to regular degreasing you can fight against the risk of fires by igniting accumulated grease.

Degreasing process

Before starting the intervention, it is essential to protect the kitchen installations (worktops with a polyane film) and to insulate the electrical connections.

The degreasing of grease extraction circuits in professional kitchens takes place in two stages:

A chemical action that consists of emulsifying grease by injecting a degreasing foam solution into the ducts and into the hood, meeting current food standards. This treatment is accompanied by rinsing with water.

Mechanical action is carried out by brushing using a ferret specially designed to operate inside the ducts.

For an optimal finish and in order to obtain an effective result, the technicians of Cleaning Services intervene in the hood manually with suitable equipment.

A clean and well-cleaned professional kitchen hood is above all a good work methodology, a qualified and available team of technicians as well as adequate equipment to carry out degreasing !

Need advice or intervention for the maintenance of your kitchen hoods ? Any information about cleaning extraction systems in industry and dust removal from air conditioning systems ? Cleaning Services experts answer your questions as soon as possible. Contact us without delay !

A reminder of the regulations concerning the degreasing of a professional hood

The legislation very clearly provides for periodic cleaning and disinfection of the entire system. Indeed, article GC18 of the French Official Journal, relating to the maintenance of fat extraction circuits in professional kitchens, specifies that:

- Cooking appliances must be kept in good working order and cleaned as often as necessary

- Stale air extraction systems such as oily fumes must be maintained regularly and swept at least twice a year